Retired firefighter Dusty Miller builds one hot RD!

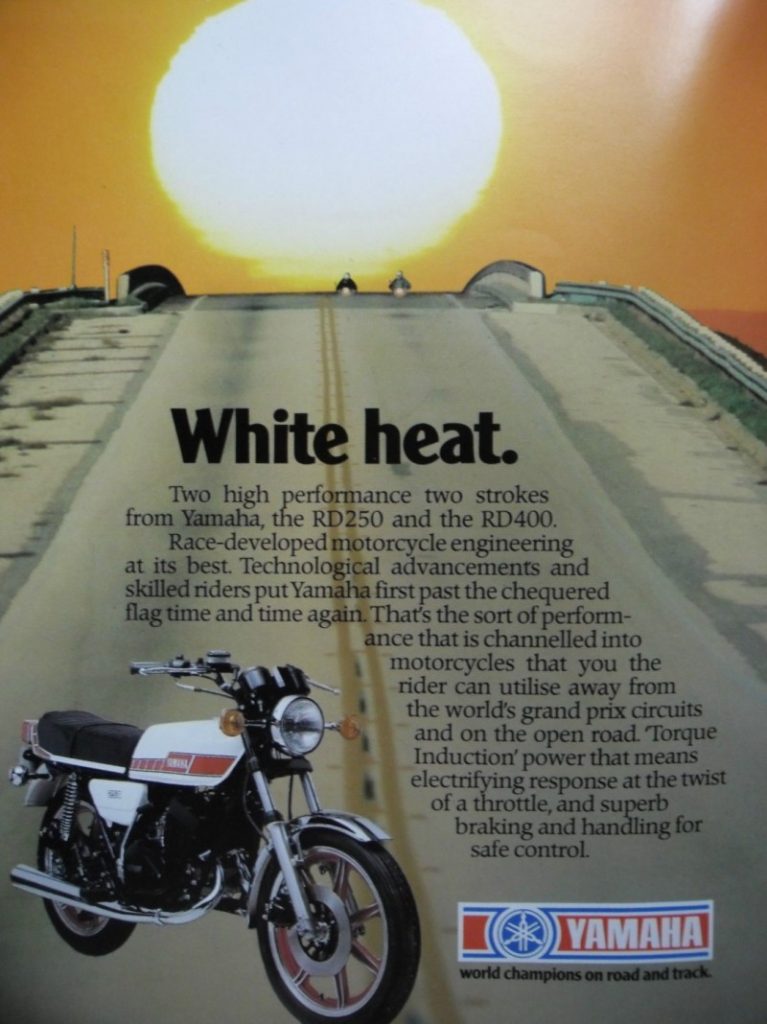

In 1975, the Yamaha RD400 appeared as the evolution of the RD350, featuring 51cc more displacement, new cases/barrels/head, a new airbox design, and a rubber-mounted engine.

“The 40bhp two-stroke had been considerably developed to make it bigger, smoother, quieter, faster and longer-lived.” —Classic Bike Hub

Reviewers raved about the bike’s potent power-to-weight ratio, race-tuned soundtrack, improved torque and comfort, and stellar bang-for-buck quotient. The RD400E was the penultimate model, available 1977-78, and many consider it the best buy of the bunch for those in the market for a 400 stroker.

One man who knows these bikes inside and out is our friend Dusty Miller, a retired UK firefighter who’s loved these bikes since his boyhood:

“Ever since I had my first 50cc bike, I’ve enjoyed modifying them, with varying results! I bought an RD400E in 1986 — a bike I had always wanted when growing up — and I kept that 400 for 13 years.”

Now, 35 years after he bought his first 400E, Dusty has just completed another 400cc stroker — and what a giant-killer it is! Over the years, Dusty has built a succession of hybrids, starting with air-cooled twin-shock frames and decking them out with liquid-cooled engines, RGV running gear, monoshock conversions, and more — much like his RD400 “Hybritza” we recently featured.

This time around, Dusty again started with a bare RD250 frame, but he decided to play things a bit closer to the chest:

“This time I wanted to build a twin-shock 400, and I wanted it to look like a standardish 400, with some changes. It would have a standard paint scheme — white/red speedblocks like the TZ-style schemes Yamaha are known for, standard instruments, standard tank and seat — all the parts that identify it as an RD400E, basically.”

But it would be no basic RD400E. It would have RGV front/rear wheels and forks, modern tires, better brakes, improved suspension, and enough trick details to keep the most avid RD guru poking around the bike for hours.

We don’t want to spoil the fun, so we’ll let Dusty give you the full story on this incredible RD400 hybrid/restomod.

Yamaha RD400 Restomod: In the Builder’s Words

Make, model and year of the bike.

I was given a Yamaha RD250D frame by a friend of mine. It’s dated 1977, going by the frame numbers. There was no paperwork with it when he gave it to me — it was originally a German bike, so I had to jump through some hoops to get a UK registration, but once I got an age-related registration, it became a viable project.

Why was this bike built?

My friend Alex had this frame stored in his garage, and gave it to me so I could cut out the bottom brace/side stand mount and get it welded into my Hybritza, as that frame was missing the cross brace. I removed it very carefully so as to not damage the frame, as it was in great condition for its age. Once I’d cut the cross section out, I carried on with the Hybritza build and consigned this frame to the shed. As time went on, I started to think about a new project, and thought it would be good to build another air-cooled 400. Having the frame in the shed sealed the idea, and once I got the registration assigned to it, the project went “live.” So all I had was the frame, a pair of RGV forks and front wheel left over from a previous project, and a brand new RGV rear wheel that I’d bought when I saw it cheap on eBay (coz you never know when you are gonna need an NOS rear wheel!), but nothing else. I had recently sold one of my LC hybrid builds, so would use the funds to build this 400, but knew it was quite a task as so many parts had to be found for it. Starting with a frame is definitely not the best way to build a bike!

What was the design concept and what influenced the build?

I have built some air-cooled 400’s in the past, and all have had monoshock conversions. This time I wanted to build a twin-shock 400, and I wanted it to look like a standardish 400, with some changes. It would have a standard paint scheme — white/red speedblocks like the TZ-style schemes Yamaha are known for, standard instruments, standard tank and seat — all the parts that identify it as an RD400E, basically.

I would use the RGV front and rear wheels and forks, giving me 17″ wheels and therefore modern tyres, better brakes, and improved suspension. It would have to be comfortable, so normal type bars — not clip ons — and rearsets that didn’t necessitate a hip replacement every time you rode the bike!

What custom work was done to the bike ?

Having built the Cafe racer/Hybritza bike just prior to this, I knew I would need some engineering work done to the frame, i.e. a new coil-mount for the Banshee coils, some serious work to the frame for the chain-run clearance due to using the wider rear wheel, and a couple of other minor mods.

Chain run was sorted by cutting a pocket out of the frame above and below the swingarm pivot where the chain passes by. Solid bar was then inserted into the frame tube and fully welded in, and then the solid bar was cut back to allow the chain to pass by without touching the frame. I did exactly the same on the Hybritza, as it’s the same frame and swingarm/wheel set up, so I knew it needed doing. It makes for a very strong modification with no loss of integrity or strength in the frame tube. I also got the engineering guys to make me a custom undertray from 3mm ali sheet, and they bent and formed it to fit the frame, following a pattern I made up in cardboard. I then polished it.

One of the guys on Norbo’s “Rdlccrazy” forum produces billet yokes, designed to take RGV forks into an LC headstock. As the LC and AC headstocks are the same dimensions, I used his yokes for this build. The added bonus, apart from being beautifully made and really light and strong, is they have adjustable lock stops, so I could get the stops adjusted without frame alterations.

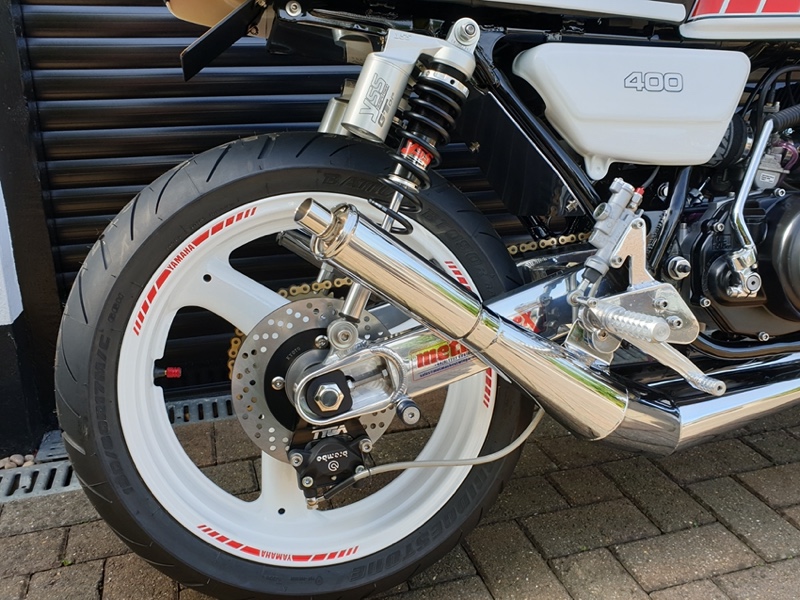

The swingarm was always going to be a Metmachex arm. I have used them on previous builds and they are simply awesome. I approached Garry and Tamsyn at Metmachex with the idea, and Garry produced the world’s first Metmachex RD400/RGV rear-wheel swingarm — according to him!

.

I had to take the frame up to Derby so he could alter the top shock mounts, as they needed to be sat farther away from the frame due to the wider swingarm. He knocked up two new top mounts and welded them onto the frame, and this means the shocks sit perfectly vertical. Another engineer I know made up two extension blocks for the shocks which raise the ride height to help compensate for the 17″ rear wheel. I still have further adjustment should I need it.

.

The air-cooled bikes had a really annoying under-tank balance pipe that linked the two halves of the tank together. To remove the tank meant releasing one end of the pipe and spilling fuel over the engine. I did away with the balance pipe, having the underside welded shut and a second petrol tap added to mimic the one on the left side of the tank, so now each carb has it’s own hi-flow tap, and no more spilt fuel!

The petrol tank I found on eBay, perfect inside and out but the wrong colour! I got a great deal on a standard seat, side panel, and tail piece — really hard to find parts in the UK, and expensive normally. A mate of a mate re-sculptured the seat for me — I wanted it to look more like an LC seat and not so big, so he cut some foam out from the standard profile and made a new cover for it. I had to buy an electrics plate, battery box, oil tank, new pattern loom. New headlight and rear light, chain and sprockets, tyres, wheel bearings, taper head bearings, new switchgear, new cables, new speedo drive, new cush rubbers in the rear hub, new Brembo rear caliper and Tyga RGV carrier.

I rebuilt the forks with new seals and heavier oil, and polished them myself. My mate Jamie powder-coated the wheels and other parts, and cerakoted a lot of the engine parts. The shocks were a big spend — YSS G series twin shocks for an XJR1300 — really great value for money. I’ve had a few of their monoshocks on other builds and they are great.

Mark Cordwell did the paintwork. He does all my bikes now. He used a bright white instead of the creamier Yamaha white, so it would match the bright white wheels. The paint is flawless and follows the standard Yamaha “white heat” scheme from the 80’s “E and F” bikes. I had the front mudguard painted red as a nod to the TZ style, and also I think it looks good against a white wheel.

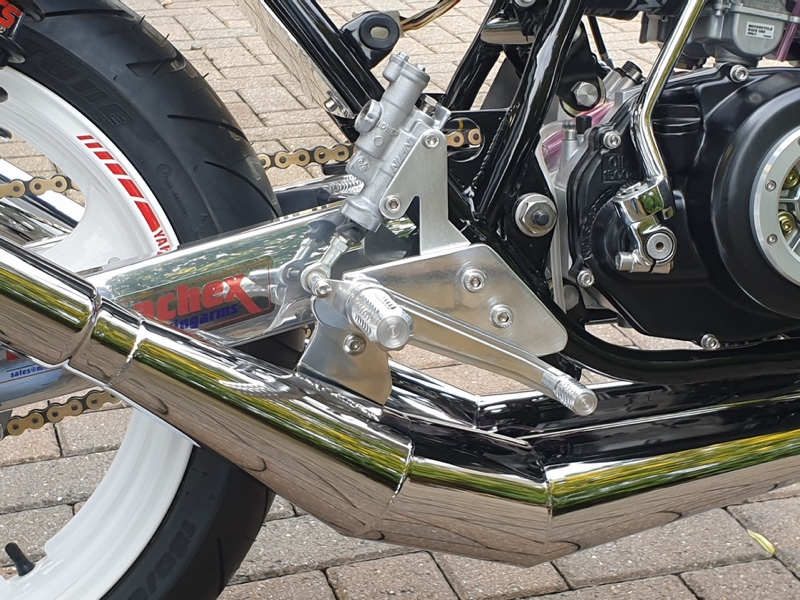

I used Nissin calipers for the front, new brake lines with stainless fittings, too. Rear master cylinder is a new Moto X item with an integral reservoir. I drew up the rearset shape and my engineering guys cut them on the plasma cutter from 12mm ali plate. I then bought new foot controls from eBay and drilled the necessary mounting holes and polished them up.

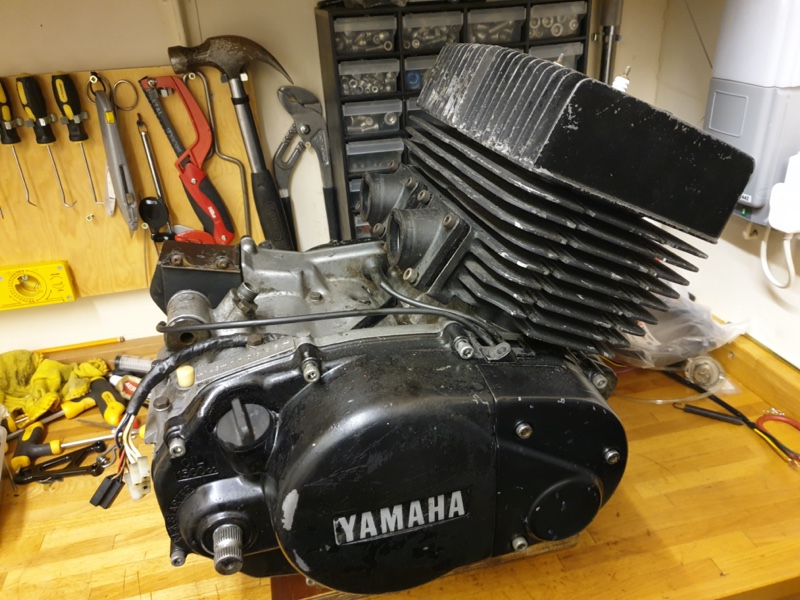

Another major component to source was the engine. When I built the Hybritza, I couldn’t find an RD400E engine for love nor money, and ended up using a PV engine in that build. This time I got to win a 400E engine complete on eBay. It needed a total rebuild, as it had been stored in a garage or years.

I did a total strip-down, and Paul at PJME did a crank rebuild and a rebore with new Mitaka pistons and rings. Jamie Cerakoted the barrels and heads and polished the fin edges for me. I completely rebuilt the bottom end after Jamie vapour-blasted the cases. New gearbox bearings, new billet clutch, new clutch pack, every fastener, seal, gasket and circlip replaced with new Yamaha parts.

Simon at Siberdyne did the clear clutch and generator windows using 6mm toughened glass in anodised aluminium housings. Inlets are billet, carbs are new PWK 28’s, foam pods are Ramairs.

The pipes are new, small-can Allspeeds in chrome, just like I had on my first 400E back in 1986! They kick up nicely at the back, and sound fantastic. I had some stainless tube welded onto the end caps to change the look of the pipes just a bit — I like detail changes, it makes it just a bit different.

Alex gifted me some standard instruments which I completely stripped, cleaned and reassembled, respraying the dial edges. Clock cups are powder-coated. Bars are Renthal low bars that were originally anodised black, but I polished that off (took ages!).

The billet top yoke has a neat handlebar clamp conversion so I could fit a temp gauge that will read both cylinders. Possibly not that useful in use, but it’s a nice touch and again, a bit different, and does give an indication of how even the cylinders are for temperature.

The taillight is recessed on a special bracket that bolts to the underside of the seat. I did this on a previous build 12 years ago, and kept the card template. My engineering guys cut and bent the bracket to shape, and the light tucks in nicely to the rear cowl after I had cut out the hole to allow it to recess.

Seat side strips are stainless pattern items, painted by Mark. Front master cylinder reservoir is a billet item from Australia. Dog leg levers are by Titax. Probably missed a few details, but that’s a general run down!

Does the bike have a nickname ?

No, it’s just my RD400E hybrid.

What’s it like to ride ?

It’s ready to go once I find the time to bleed the brakes — the last job to do now. It should be fairly comfortable — rearsets aren’t too extreme, seat hasn’t had too much foam removed, and the bars are just right. I did build a 400 with a race seat in the past, and it was torture after 30-odd miles — any more than that would possibly mean never fathering children, so I learnt my lesson and kept a standardish seat. Forks and rear shocks are far better than an original set up, with plenty of adjustment, especially at the rear, and previous builds have proved the RGV running gear can work really well with these old frames, so handling should be pretty good, and braking will be a vast improvement over a stock 400.

.

Anything else you are proud of?

I’m pleased it’s done. It’s been quite hard finding some of the used air-cooled parts, especially in good condition. I bought three oil tanks before I found once that wasn’t rusty/dented/full of blasting media! You can still get a fair few parts new from Yamaha, but other items are NLA and hard to find in good, used condition. Parts prices are crazy in the UK — anything two-stroke related from the late ’70s/80s fetches a premium, and Covid has only accelerated the price hikes it would seem. But I’m glad I did another 400, especially after doing three LC hybrids and the Hybritza in quick succession.

Any links to share?

There is a comprehensive build thread in Norbo’s forum. Also a dedicated engine build thread that was designed to give a stepby-step build guide, and also a crank rebuild thread to show what is involved with rebuilding a two-stroke crank.